What are DARK Factories?

For those unfamiliar with dark factories, these reflect the pinnacle of automation. Whereas people and machines work alongside one another in a smart factory, dark factories do not need a single person present on the premises.

Dark factories (where the lights are off) can work 24*7 with automated robots, which will increase productivity with zero error in manufacturing processes.

This concept has taken on immediate value as the COVID-19 pandemic takes hold. The idea of a fully functional factory floor that needs no permanent human staff means uninterrupted production output. Nevertheless, many organizations are unable or unwilling to commit to this level of automation. Smart factories still dramatically reduce the number of workers needed as the simplest tasks are automated. During the time of pandemic industries with advanced machinery had a higher chance of continuing their manufacturing processes. The pandemic has made us realize that we need to have more sophisticated and automated systems for the industries to run smoothly, and surely it leads us to the implementation of Dark factories. With fully automated factories we will never have to worry or wait to begin the front-line production. It can be turned into a continuous process. Incorporating lights off methodologies into the floor plan saves cost, space, and time. Research reveals that a fully automated factory can increase productivity even up to 250% and the errors decreased by 80%.

The Changying Precision Technology Company was the first company in China to implement DARK Factory. This mobile phone company used to employ 650 workers and now it only needs 60.

Philips, which is running a manufacturing unit in the Netherlands to produce electric razors produces 15 million electric razors every year. Who is running the show? 128 robots. The only phase where they seek human intervention is during quality assurance, where 9 humans are employed.

Initially, the role of robots for manufacturing was focused on using them for dull, dirty, and dangerous tasks- the 3 D tasks. However now the focus is on using entirely autonomous machines.

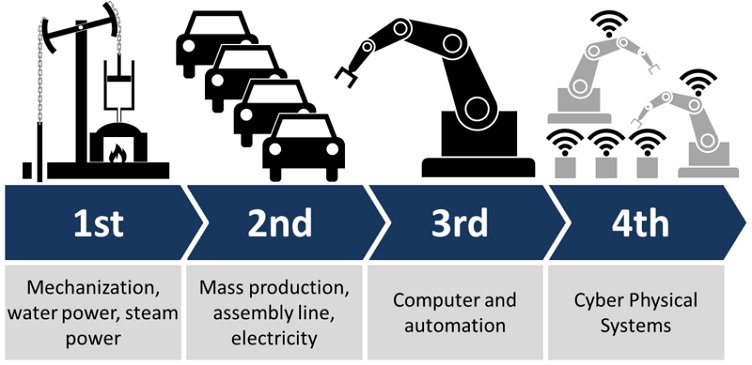

Adapting to dark factories cannot be seen as a drastic change, as over a period of time people have seen the advancements made in the fields of technology and are getting used to it. Factories are already moving towards an automated industry and moreover, it has become necessary for industries to be more advanced and updated. Upgrading from a smart factory to a dark factory can be more of an economic decision.

No doubt within a time span of five to ten years’ industries across the world will embrace the change of becoming smart factories and those who already run a smart factory will definitely transform to fully automated ‘Dark Factories’.

The supremacy of Dark Factories is near and soon the world will see the transformation to Dark factories. No doubt Dark Factories will definitely pave the way to a brighter future.